Samatrix reacts to beach side pipe failure

A team from samatrix recently attended a call out from one our clients, where an existing cast iron manifold had failed, at one of their pumping stations located in a very popular beauty spot.

The pipework estimated to be in the region of 60 years old, had failed downstream of the final available flange connection within a dry well pumping station. The pumping station is located adjacent to a popular beach and car park. The samatrix team carried out a temporary repair using a temporary fabricated clamp.

However the existing pipe damage was such that a small movement in the pipe manifold (due to a flange adaptor not being restrained) led to a complete failure and complete pipe rupture.

The failure occured during the recent heat wave, with the beach and car park full with holidaymakers and daytrippers, this required a swift and minimal disruptive remedy. To maintain the pumpng station flows our client required 24/7 tanker availability.

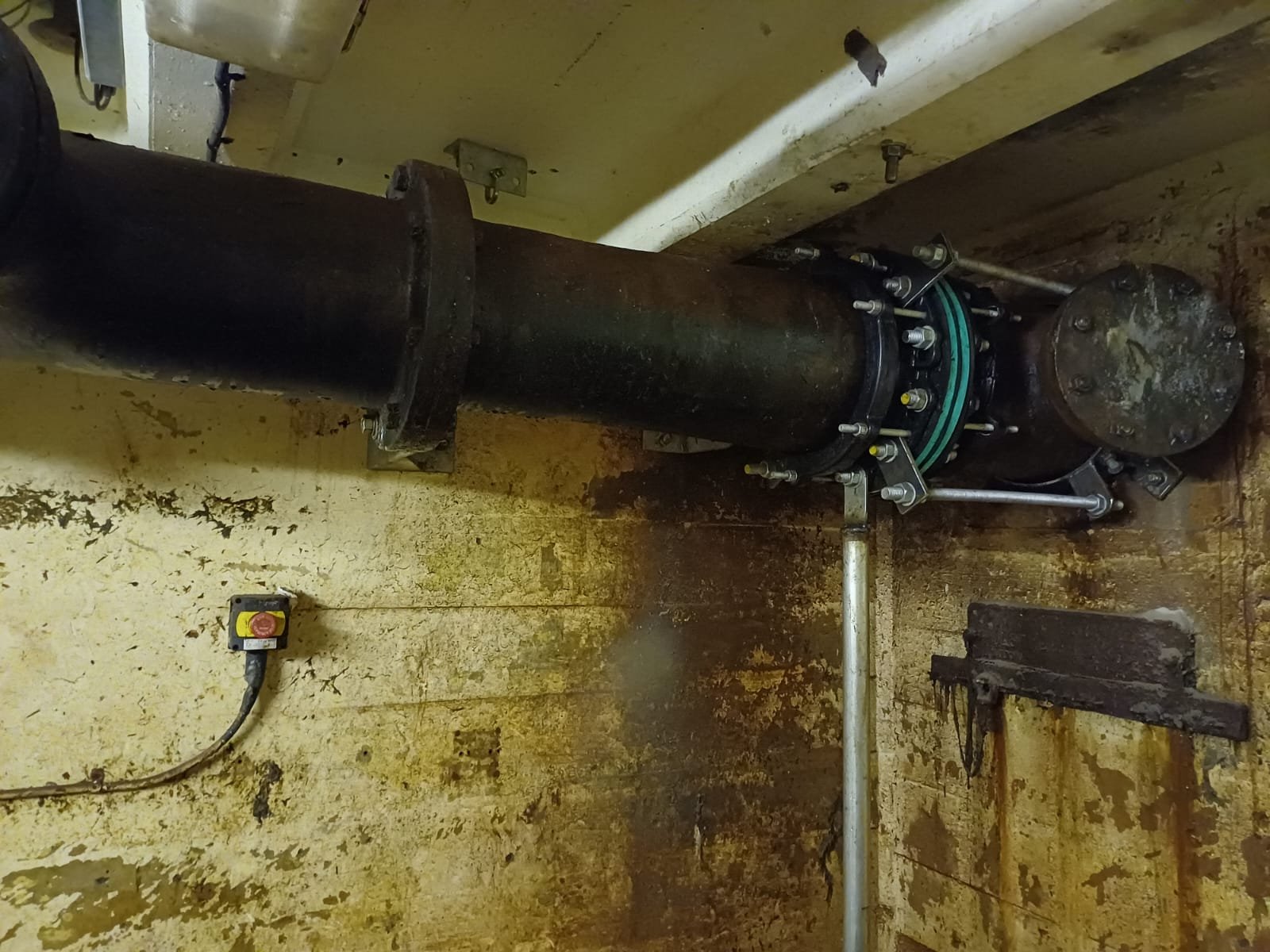

Once the main was allowed to drain back, the dry well chamber contents tankered away, and the chamber cleaned our team attended site to formulate a plan. A number of ideas were tabled and time being of the essence, it was opted to use equipment readily available and to fabricate brackets and supports to limit any possible future pipe movement. To compound the problem the fractured pipe was on an imperial taper/tee special, cast into the adjacent structural wall.

The repair solution consisted of two pipe adpators fitted back to back with spacers to close the gap created by the pipe break. The adaptors were tied to a fabricated restraining clamp which was further anchored to the concrete structure, along with horizontal support brackets to prevent axial movement. Existing flange adpators were also fitted with restraint tie bars.

On completion of these remedial works, the repair proved successful and allowed the pumping station to be returned to normal operation, much to the relief of our client.